Range of Services

Understanding Customer Requirements

Irvin provides the most extensive range of engineering services to enhance

the final product and provide an optimum solution. Services include:

• Fabric Design

• System Engineering

• Systems Analysis

• Mechanical Design

• Control Systems

• Product Testing

• Program Management

• Rigging and packing

Fabric

Design

Fabric

design is central to all of Irvin's product development. Our engineers

are experts in the design and specification of fabrics including broadcloth,

tape, webbing, cords, ropes and coated fabrics. Irvin is also expert in

the joining of all classes of fabrics to create efficient structures for

these dynamic fabric-based parachute systems.

Irvin

engineers work with all modern fibers, understand several of the current

'miracle' fibers and constantly track emerging technologies in fibers,

fabrics, film and coatings.

System Engineering

Irvin applies extraordinary levels of System Engineering to each project,

delivering value to customers from the system engineering process while

containing unnecessary costs. System Engineering tools including Integrated

Master Schedule/Integrated Master Plan, Specification Compliance, Validation

Tracking and Risk Assessment are included in all of our programs.

In addition to the development of internal specifications for fabric,

parts and equipment, Irvin's System Engineering process also includes

programmatic test plans, test reports, final verification reports and

matrices.

More rigorous System Engineering programs such as Technical Performance Measurements, Risk Item Tracking/Database, and Multi-Level Specification Requirements Databases are used as required by the size of the program or when directed by the customer.

Systems

Analysis

Multiple

stress and structural simulation capabilities are an integral part of

Irvin's engineering services.

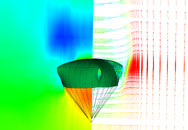

Parachute Trajectory Modeling and Simulation

Extensive analysis capability exists within Irvin's trajectory modeling

and simulation.

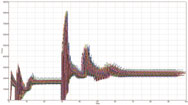

Irvin engineers use Monte Carlo simulations to predict and optimize the performance of extraction and delivery systems. |

•

Irvin's primary parachute deployment, inflation and trajectory application,

Decelerator Dynamics (DCLDYN) has its original algorithm roots dating

to the Apollo program. Significant capabilities and validation have been

added over the years. Irvin's parachute trajectory simulation includes

all of the higher order terms of parachute deployment and inflation including:

—Time dependent parachute drag area, including highly nonlinear responses

—Parachute mass growth during inflation

—High order cargo body aerodynamics

—A variant that assesses vehicle reorientation events

•

Modeling of aircraft floor for aerial delivery application, including

ramp tip-off simulation

• Inputs for variable atmospheres, Earth or off-planet

• Wind profiles

• Temperature/density variations

• Ejection seat modeling with crew acceleration exposure computations

• Deployment forces such as mortar or tractor rocket

• Landing brake parachute modeling for the aircraft

• High quality parachute simulation for coupling with a customer

vehicle

•Development

of a trajectory Monte Carlo simulation, implemented as scripts, which

provide outer loop execution of the basic DCLDYN application, this capability

includes:

—Primary model inputs which the user can vary, such as:

a. Parachute drag area

b. Inflation characteristics

c. Vehicle aerodynamics

d. Deployment initial conditions such as airspeed and position

—Flight atmosphere conditions

a. Prevailing winds

b. Density profile

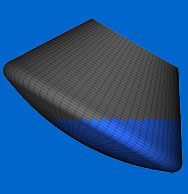

Finite

Element Analysis of Metal Parts

Stress and structural linear and nonlinear analysis of metal parts

improve designs, reduce costs and shorten time to market for many of Irvin's

customers. Irvin's engineers provide quick and accurate linear analysis

and a capability for structural optimization in both topology and topography.

Irvin has used this analysis to quickly assess potential improvements

to baseline designs. These analysis results, further reviewed in product

testing, produced significant results in the optimization of the final

design solution.

Irvin's expertise also exists in nonlinear analysis of materials and design

geometry. Irvin has successfully analyzed load cases with metal parts

and their dynamic loading in the parachute deployment train and successfully

implemented design changes to compensate for potential load cases.

Fabric

Structure and Impact Dynamics Analysis

Irvin's capabilities in the analysis of fabric structures and impact

dynamics is unmatched. Irvin's expertise provides analyses and solutions

to large deformations found in both fabric structures and fabric impact

dynamics. Irvin is the leader in the analysis of impact dynamics with

airbags for landing of aircraft and spacecraft.

In the area of inflated structure design, Irvin has advanced the technique

of using quasi-steady results from its Finite Element Analysis (FEA) capability.

Irvin engineers can analyze the steady state loading conditions and analyze

and manage the challenges associated with large deformations of structures,

such as the transition from constructed to inflated shape of a fabric

structure.

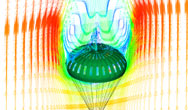

Fluid Structure Interaction

Irvin couples Computational Fluid Dynamics (CFD) and Finite Element

Analysis to create a Fluid Structure Interaction (FSI) analysis capability.

Irvin engineers were the first to use FSI analysis for parachute engineering

solutions. The purpose of these simulations is to analyze systems where

the loading mechanism and the structural deformation are linked and largely

inseparable. The parachute is the perfect example of this application.

Irvin provides analysis of the shape of the parachute and its interaction

with the flowfield as it varies with flight condition; yet the flight

condition is dependent upon the performance and shape of the parachute.

Irvin’s water landing analysis accurately predicts landing loads. Irvin is the leading authority for prediction of water landing loads for future manned spacecraft. |

Irvin's

work with this analysis includes two primary value-added capabilities,

•

the simulation of parachute structures in steady state flight.

•

the landing dynamics of spacecraft and other vehicles in a water landing

condition.

As

part of its engineering solutions, Irvin engineers identify, analyze,

and correct random glide flight modes of otherwise non-gliding parachute

systems.

In the field of water landing, Irvin provides validation analysis comparing

landing simulations to test data and can predict landing loads.

Flotation Stability-A Unique Capability

Irvin's flotation stability analysis is unique in the industry providing

automated processing of vehicle buoyancy plane and moment. Irvin's FloatStab

analysis allows the rapid analysis of basic vehicle shape and augmented

shapes, with deployed flotation or stabilization devices for planned and

emergency water landings.

Irvin engineers design Attach Release Mechanisms that pilots operate to release the parachute after a Spin/Stall recovery. |

Mechanical

Design

Irvin's

mechanical design expertise includes design of mechanical parts and mechanisms,

as well as design of pyrotechnic devices.

Parts and Mechanisms

Metal parts and mechanisms are key elements of all recovery systems. These

include metal fittings in the parachute structure, servo actuated devices,

adaptive structures to interface with the customer vehicle, parachute

compartmentation, and integration with pyrotechnic class controls and

actuators.

Irvin's experienced staff is expert in the mechanical design of these

critical components. Irvin engineers work with a wide range of tools for

stress analysis, including linear, non-linear and topology and topography

optimization.

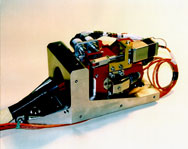

Pyrotechnic Devices

• Parachute Deployment Mortars:

Irvin's proven mortar family capabilities range from parachutes of 1 lb.

or less to parachutes of approximately 185 lbs. The average parachute

deployment speed is approximately 110 fps, providing excellent penetration

of vehicle wake flowfields and results in high deployment reliability.

In the 20 to 100 lb. range, multiple mortar designs exist providing flexibility

in designing parachute installation.

•

Parachute Release Cutters:

Irvin has a wide variety of existing designs for pyrotechnically activated

parachute cutters. These are often used for parachute sequencing such

as drogue parachute release and main parachute deployment.

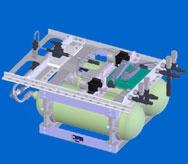

• Inflation Systems:

Multiple designs are available for the inflation and pressure control

of inflatable structures such as airbags.

• Other Devices:

Door thrusters, drogue guns and tractor rockets are also part of Irvin's

design capabilities.

Irvin designs a wide range of reliable parachute control systems for a number of aircraft. |

Control

Systems

Whether

for test, demonstration or production flight, Irvin controllers integrate

easily with the pyrotechnic and electro-mechanical class actuators common

in recovery systems.

Irvin's controllers fly daily in Spin/Stall Recovery Systems for many

customers. These systems control both pyrotechnic and servomotor devices.

The integral Built In Test (BIT) systems have both enhanced flight test

safety and reduced system maintenance between flights.

In addition, customers can count on Irvin's knowledge of recovery system

controller design to support their own design. Our full knowledge of BIT

integration and pyrotechnic device safety and testing are available to

support our customers controller design and development requirements.

Product

Testing

Irvin's

test capabilities are unique in the industry. Irvin's engineers are fully

versed with all aspects of product testing from seam and joint element

testing through highly complex, supersonic wind tunnel testing. Irvin's

experience and knowledge base ensures that tests are conducted with the

precision required to validate product performance to federal standards.

Test capabilities include:

Tensile Test

Irvin's computer controlled tensile test machines are capable of testing

the lightest sewing threads up to the highest tensile elements. This test

capability is also used for parachute seam and joint testing to validate

and verify assumptions made in our Design Analysis process.

Flight Testing & Qualification of Parachute Systems

Irvin's flight testing and parachute system qualification is unsurpassed

in the industry. Irvin's engineers regularly design and conduct parachute

flight tests with payloads ranging from 2 lbs. up to 4,500 lbs. in weight.

Irvin can configure any required weight or mass property. Irvin's test

equipment includes programmer parachutes, time delay cutters and electronic

sequencers that enable Irvin engineers to conduct testing at the highest

fidelity possible. Irvin's experienced team conducts all aspects of aircraft

drop testing including drop zone control, load masters and test jumpers.

Irvin also has proven experience working with a number of government agencies

in the design and execution of drop tests with payloads up to 42,000 lbs.

in weight. Irvin has developed the technology which will double the delivered

weight.

Irvin maintains dedicated test and drop facilities in several locations

to accommodate and respond to various customer requirements. Typical test

measurements include video, photo and on board instrumentation (loads,

pressure, altitude, acceleration and GPS). Design enhancements and modifications

are made on site as part of Irvin's continuing product development. Rigging

and packing tables are also on site to facilitate training and the development

of procedures. Several delivery aircraft are available for parachute testing

including Otter, Skyvan, B-25, C-123 and L-39. Dummy, live testing, test

vehicles with a wide range of payloads are available and utilized as part

of the parachute test and qualification. Depending on requirements, several

drop zones are available with locations in Eloy, Yuma, and Kingman Arizona

and Lake Elsinore, California.

Airbag Drop Testing

Irvin engineers are expert in scaled and full-scale testing of airbag

landing systems. Local drop test facilities are available for testing

of scaled and full scale vehicle models to 4500 lbs. depending on vehicle

geometry. Other facilities are available for larger size and weight vehicles

up to and including 50,000 to 60,000 lb. weight class and full scale spacecraft/aircraft

geometry.

Irvin engineers are fully versed in the scaling of test results and relevant

scaling laws. Irvin has published detailed comparisons between scaled

testing and full scale simulation.

Water Landing Systems

Irvin is expert in the testing of water landing systems, including direct

entry and airbag landing attenuation for water landing. Irvin engineers

are fully conversant in requirements for full scale testing and the application

of sub-scale testing for both water entry and post landing flotation and

stability.

Environmental Testing

Irvin conducts a full range of environmental testing of components and

recovery systems. Qualification tests include:

• Vibration and Shock

• Thermal

• Vacuum

• Thermal/Vacuum

• EMI/EMC

• Explosive Atmosphere

• Sand and Dust

• Salt Fog

• Rain Environment

• Impact Testing

Acceptance Testing

Irvin engineers are fully versed in the development and execution of acceptance

tests for a specific component or part. Tests are developed and reviewed

with the customer during program execution. Equally important, the procedures

and test articles are typically maintained and updated over the life of

the product.

A new product that requires additional tests typically results in an update

to the acceptance test, resulting in further observation of that product

feature for future years.

Installation Testing

As required, Irvin provides detailed installation and checkout procedures.

These are often finalized in the field as Irvin engineers complete equipment

installation on the aircraft or system. Recovery system installation,

checkout procedures, and detailed packing instructions are completed with

the operator technicians during a hands-on training process.

Out year support, including an "Aircraft On Ground" class response

is available for customers that require that level of support.

Wind Tunnel Testing

Irvin engineers design and operate a wide range of wind tunnel tests ranging

from low speed to full size tests in the NASA AMES tunnel through supersonic

scale model testing in the AEDC Transonic Tunnel.

Data Collection

Irvin employs the finest data collection and analysis tools. Irvin's test

vehicles are typically instrumented with field computers collecting data

at rates up to 5,000 Hz. A typical instrumented drop will measure 3 axis

accelerations, riser loads, pitot/static pressure, and vehicle inclination.

The drop also includes an on board camera to film deployment events. Data

collected is typically available for review within two hours of the test.

Program Management

Irvin's

experienced managers provide customers extensive and thorough program

management ensuring each program meets identified objectives.

Irvin recognizes that effective project management is one of the key elements

required to ensure successful execution of any project. Irvin has a team

of experienced Project Managers who prepare a detailed report of cost,

schedule, and technical performance on a regular monthly basis. This cost,

schedule and technical performance reporting can be a method to achieve

significant cost improvement.

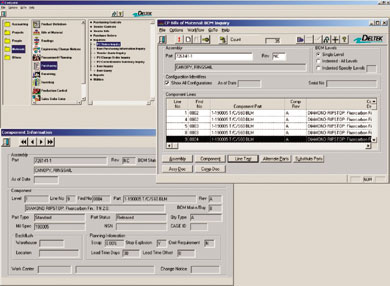

Irvin routinely utilizes schedule management tools such as MS Project

to develop an Integrated Master Schedule and then monitor and track progress.

Irvin tracks costs using the Deltek Costpoint program, selected because

of its heritage and acceptance by government cost agencies.

In addition to tracking against the agreed contract cost, the Irvin Program

Manager regularly assesses progress against each Work Breakdown Schedule

(WBS) item and compares the expenditures against the work completed. This

data is presented via Estimate to Complete / Estimate at Complete reports.

These data, when combined with the progress tracking and the Integrated

Master Schedule allows Earned Value to be assessed and reported.

Irvin has an established supplier base to support its engineering and

large-scale manufacturing operations. All suppliers of parts and materials

are assessed against Irvin requirements before being entered onto an Approved

Vendors List.

|

||

|

|

Configuration

Management

Irvin has a well-established Configuration Management program, documenting

over 85 years of parachute design and manufacture. Configuration control

is used to manage all changes to design and documentation throughout the

life of a product, from the initial release of sketches for sample manufacture

to the final Technical Data Package.

Rigging

and Packing

Irvin

maintains a full parachute rigging and packing capability that includes

packing tables, rams for pressure packing and an autoclaving capability.

These capabilities allow pressure packing of decelerator systems to world-class

packing densities. Packing tables can be configured to provide a clear

run of over 280 feet of table length allowing the largest parachutes to

be rigged and packed.

| RETURN TO TOP | |

Home

| A Message From The President | About

Us

What's New | Products

| Engineering | Manufacturing

| Contact Us

Markets We Serve

©

2005 Irvin Aerospace

|

|

The graph illustrates the Monte Carlo results, a capability within Irvin’s DCLDYN application, where the engineer can investigate system performance sensitivity. The application of probability analysis creates a more robust solution and helps ensure the safety of the aircrew and aircraft. |

|

|

|

| These Von Mises stress contours depict the results of a complex loading scenario, almost impossible to assess using more traditional approaches. This analysis reduces cost of testing and speeds time to useability. | |

|

|

| Simulations incorporating airbag venting, blockage and active control allowed accurate analysis of the Kistler K-1 Spacecraft landing system. | |

|

|

The ability to visualize the airflow around this personnel parachute provides the designers with a new perspective and the ability to optimize the design. |

|

|

|

Irvin engineers can simulate small modifications in canopy size and form to optimize the design and improve performance instead of unnecessary cost and time consuming flight tests. |

|

|

|

| The ability to predict flotation behavior complements Irvin’s recovery system design and water entry simulations, delivering a more complete systems analysis. | |

|

|

| Irvin has an entire system of mortars that rapidly deploy the parachute and are applicable to all aircraft and spacecraft. | |

|

|

The reliability of Irvin's cutter systems delivers safe and predictable system performance. |

|

|

|

| Robust, modular inflation systems provide a flexible interface for a number of inflatable fabric systems. | |

|

|

In-house testing of the parachute pack delivers rapid results. |

|

|

|

Irvin, under contract to Lockheed Martin, supplied the parachute system to demonstrate a launch pad emergency abort system for a future manned spacecraft. |

|

|

|

Extensive on site capabilities at several locations provide delivery aircraft, rigging and packing, on site parachute modifications and electronic sensing for test. |

|

|

|

The application of Irvin’s Finite Element Analysis technology in parallel with Irvin’s System Engineering component design resulted in a successful test series of this airbag landing system for a future manned spacecraft. |

|

|

|

Wind tunnel parachute testing of the successful NASA space shuttle landing brake system. |

|

|

|

Irvin’s extensive packing and rigging capabilities include packing tables long enough to rig and pack the world’s largest parachute cluster. |

|